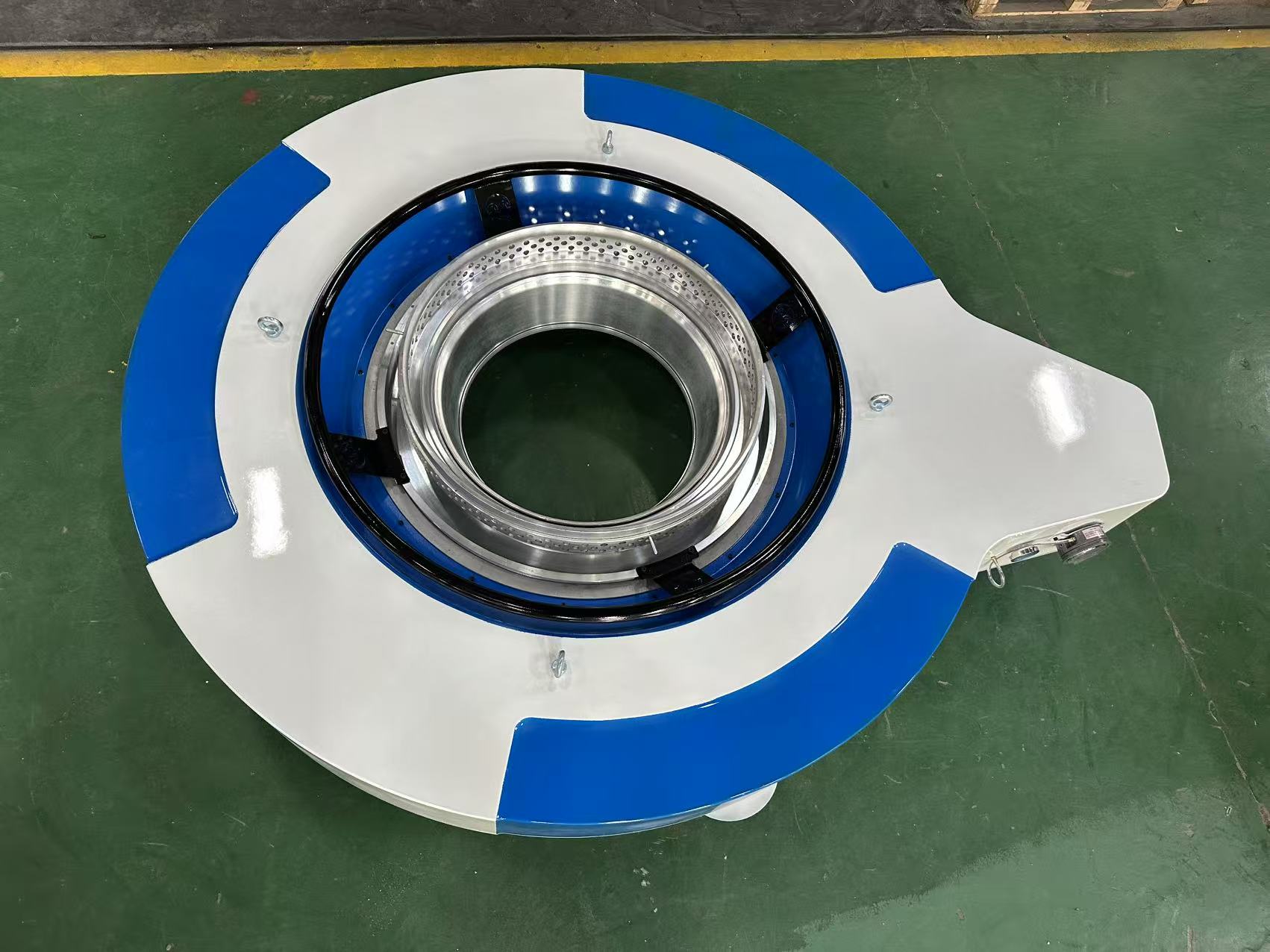

Multi-layer Co Extrusion Agricultural Blown Film Machine air ring

The new series of automatic air ring system optimizes the film blowing process, combined with the convenient air temperature adjustment device, significantly increases the output of the production line, and significantly improves the thickness tolerance. The thickness error is reduced by 50% compared with that without a control system, the theoretical limit deviation reaches within +-4%, and the 2sigma value is controlled at 2%-3%.

Details

1、The new series of automatic air ring system optimizes the film blowing process, combined with the convenient air temperature adjustment device, significantly increases the output of the production line, and significantly improves the thickness tolerance. The thickness error is reduced by 50% compared with that without a control system, the theoretical limit deviation reaches within +-4%, and the 2sigma value is controlled at 2%-3%.

2、The new automatic air ring series is not only suitable for new production lines, but also can directly replace existing air rings to improve the performance of existing production lines. The main air ring parts are designed by computer technology and finite element analysis method, and the material is selected aviation aluminum for forging, modulating and finishing after heat treatment. All mechanical parts are strictly CNC machining and assembly, reasonable design, material selection. Scanning thickness sensor adopts plain scan X-ray probe, supporting high-precision scanning frame, suitable for composite substrate film, protective film, FFS film, packaging film with calcium carbonate, opaque film with barrier and other materials.

The air volume of the lower tuyere is kept constant, and the circumference of the upper tuyere is divided into several air ducts. Each air duct is composed of an air chamber and a heating rod. The heating rod adjusts the temperature in the air duct and controls the temperature level of each air duct.

Automatic wind ring and online detection system main parameters:

①Die 400- film width product limit width 1800mm- wind ring diameter 1800mm

②Die 450- film width product limit width 2000mm- wind ring diameter 1800mm

③Die 500- film width product limit width 2200mm- wind ring diameter 1900mm

④Die 550-film width product limit width 2400mm- wind ring diameter 1900mm

⑤Die 600- film width product limit width 2600mm- wind ring diameter 1900mm

3、Air Ring Structure and Working Principle Introduction

The automatic air ring uses a dual air outlet structure. The airflow from the lower air outlet remains constant, while the upper air outlet is divided into several air ducts along the circumference. Each air duct is composed of an air chamber and a heating rod. The temperature inside each air duct is controlled by adjusting the heating rod, allowing for individual temperature control in each duct.

4、Main Parameters of the Online Thickness Measurement System

· Product width: 1800mm, 2000mm, 2200mm, 2400mm, 2600mm

· Heating units: 120 units

· Operating speed: <200m/min

· Thickness range: 10 μm – 200 μm

· Products: PE/PA and other films

(1)Thickness Measurement

The standard low-energy, high-precision penetrating X-ray probe by Skender accurately measures the thickness of PE or PA films ranging from 10 μm to 200 μm, operating at 5 keV energy.

(2)Probe Measurement Performance is as follows:

Stripe resolution (IEC 1336-2.4.3 – 70%) | < 5 mm |

Dynamic thickness range | 10 to 2000 um |

Measurement accuracy | 1‰ or 0.1 μm, whichever is greater |

Static statistical noise (measured for 1 second) | 0.1% or 0.1 μm, whichever is greater |

Response time | 1 --- 20milliseconds |

Effect of vertical motion (jitter) on measurement | none |

Effect of environmental factors on measurement (temperature, humidity, air pressure, dust accumulation) | none |

Recommended Settings:

Air gap | 10 mm |

X-ray beam size (diameter) | 8 mm |

X-ray beam energy | 5 keV |